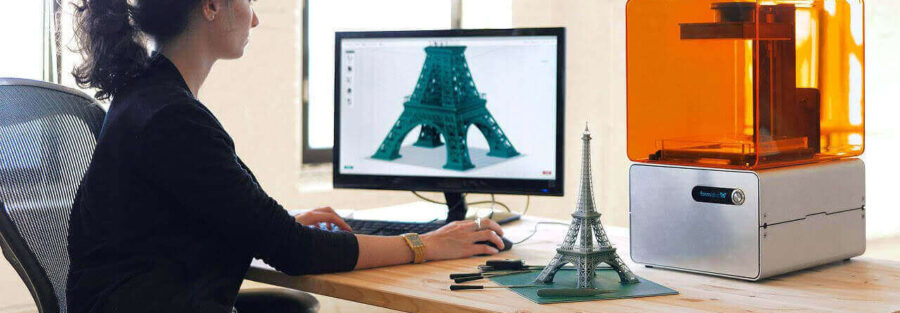

3D printing, also known as additive manufacturing, has revolutionized the manufacturing and prototyping industries. This innovative technology allows for the creation of three-dimensional objects by layering materials, resulting in quick and accurate production. With its ability to reshape traditional manufacturing processes and transform prototyping, 3D printing has opened new doors for businesses and individuals alike. In this article, we will explore how 3D printing is reshaping manufacturing and revolutionizing the world of prototyping.

Unleashing the Potential: 3D Printing Transforms Manufacturing

The advent of 3D printing has brought about a paradigm shift in the manufacturing industry. Traditional manufacturing methods often involve expensive molds and tooling, long lead times, and limited design flexibility. However, 3D printing has changed the game by eliminating the need for molds and enabling on-demand production. This technology allows manufacturers to produce complex geometric designs and customize products without the constraints of traditional manufacturing processes. As a result, companies can now reduce costs, speed up production, and optimize supply chains. Whether it’s creating intricate parts for aerospace or automotive industries or printing customized consumer products, 3D printing has unleashed a world of potential for manufacturers.

One of the key benefits of 3D printing in manufacturing is the ability to create prototypes quickly and cost-effectively. Prototyping plays a crucial role in product development as it allows for testing and validation before mass production. Traditionally, prototyping was a time-consuming and expensive process, often requiring specialized equipment and skilled labor. However, with 3D printing, designers and engineers can easily convert their digital designs into physical prototypes. This not only speeds up the prototyping phase but also allows for iterative design improvements. From concept to physical realization, 3D printing has revolutionized prototyping by empowering individuals and businesses to bring their ideas to life faster and more efficiently.

Power of Imagination: 3D Printing Revolutionizes Prototyping

The power of imagination has been amplified by the possibilities offered by 3D printing in the realm of prototyping. This technology enables designers and engineers to push the boundaries of creativity and explore innovative solutions. With 3D printing, complex and intricate designs that were once deemed impossible or impractical can now be realized. The ability to create prototypes with intricate details and fine textures has led to improved product aesthetics and functionality. Whether it’s creating a unique piece of jewelry, a customized medical device, or a prototype for architectural design, 3D printing has revolutionized the prototyping process by empowering individuals to translate their imagination into tangible objects.

Furthermore, 3D printing has democratized prototyping by reducing costs and increasing accessibility. In the past, prototyping involved significant financial investments, making it inaccessible for many individuals and small businesses. However, with the affordability and availability of 3D printing technology, prototyping has become more accessible to a wider audience. Now, anyone with a computer and a 3D printer can turn their ideas into reality, leveling the playing field and fostering innovation. This democratization of prototyping has led to a surge in creativity and entrepreneurship, as individuals and businesses can now test and refine their ideas without breaking the bank.

In conclusion, 3D printing has reshaped the manufacturing and prototyping industries, unlocking new possibilities and transforming traditional processes. With its ability to streamline production, reduce costs, and increase design freedom, 3D printing has revolutionized manufacturing. Moreover, it has empowered individuals and businesses alike to unleash their creativity and innovate through efficient and accessible prototyping. As this technology continues to advance, we can expect even more exciting developments in the manufacturing and prototyping sphere. The future of additive manufacturing holds great promise, and we can only imagine the limitless potential it will bring to industries worldwide.